Discover our Portfolio

All information at a glance

ZF Off-Highway Product Guide (Form Number 80-950-006)

This is our introductory catalog for ZF Off-Highway Solutions Minnesota Inc. products. It provides product photos and brief descriptions of the product portfolio offerings in brakes, brake actuation, valves, and controls.

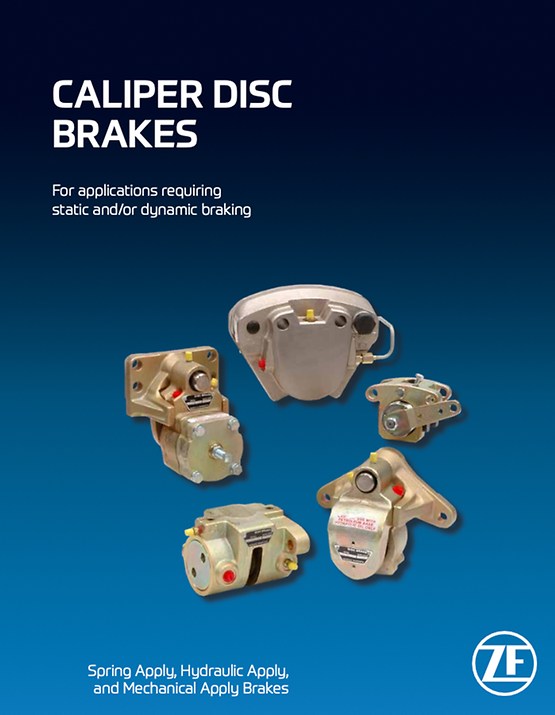

Caliper disc brakes

Providing reliable stopping & holding

With over 70 years of expertise in hydraulic disc brake technology, ZF Caliper Disc Brakes are ideal for industrial machines and mobile equipment applications. Designs include mechanical apply, hydraulic apply, and spring apply/hydraulic release. These robust designs have high pressure capabilities for hydraulic oil or brake fluid applications. There are three different series of ZF Caliper Disc Brakes available.

Your advantages:

- Installed independent of dynamic or static brake system

- Ideal for industrial machines and mobile equipment applications

- Designs available in mechanical apply, hydraulic apply, and spring apply/hydraulic release

515 Series Caliper Disc Brakes Floating Design

515 Series brakes are a floating type design, and mounted over a rotor disc using either pins or shoulder bolts. One side of the caliper is actuated to provide clamping force.

- Available for hydraulic, spring, or mechanical apply

- Designed to provide service, parking and/or emergency braking

520 Series Caliper Disc Brakes Fixed Design

ZF 520 Series Caliper Disc Brakes are a fixed type design. Each side of the caliper contains a piston that actuates to provide clamping force.

- Mounted stationary, or "fixed" relative to the rotor

- Available with various diameter actuation piston

- Uses a modulated hydraulic pressure source to control brake torque

530 Series Caliper Disc Brakes Floating Design uses Belleville Springs

5ZF 530 Series Caliper Disc Brakes are a floating type design that uses belleville springs to apply the brake and hydraulic pressure to release it. One side of the caliper is actuated to provide clamping force. Hydraulic apply models also available.

- Customized to application requirements

- Large torque range capability in off-highway applications

ZF Caliper Disc Brakes

The Solutions For Your Application

ZF Caliper Disc Brakes are ideal for providing primary, emergency, and secondary braking. Designed for applications in the agriculture, construction, mining, airport support and forestry industries.

Talk to one of our Applications Specialists to find the perfect ZF Caliper Disc Brake solution for your application.

Multiple disc brakes

Proven longer life design

ZF Multiple Disc Brakes are fully enclosed units that use coil springs and multiple friction discs to produce braking torque. These brakes are applied by coil springs and released using hydraulic pressure. Maximum brake torque is achieved when hydraulic release pressure is zero. These brakes are self-applying in that any function which reduces hydraulic release pressure will begin to initiate brake clamping force.

- Compact modular package simplifies mounting

- Designed for adverse environmental conditions

- Specifically designed to prevent piston cocking and low and high torque pressure drag

- Broad range of variants and mounting configurations including industry standard configurations

Multiple Disc Brakes Ideal for primary, emergency, and secondary braking

ZF Multiple Disc Brakes are fully enclosed and built for use in demanding conditions.

- Heat treated steel shafts for high strength and longer life

- Broad range of variants: dry, sump fluid, and flow through fluid design

- Broad range of mounting arrangements, industry standard configurations SAE, DIN, and NEMA compliant

Multiple Disc Brakes

Designed & Manufactured for Demanding Environments

ZF Multiple Disc Brakes are manufactured using high strength dectile iron housings with nitrile case and shaft seals to keep outside contaminates from entering the brake.

Available in SAE A, B, C, or D mounts with torque ranges from 113 to 2825 N-M (1000 to 25,000 lb-in) and release pressure from 6.9 to 34.5 bar (100 to 500 PSI).